Product Details

| Product name | AR FIBERGLASS CHOPPED STRANDS | ||

| MOQ | ≥1000KG | ||

| Zro2 Content | 14.5% & 16.5% | ||

| Application | 1. Mortar and concrete reinforcement (GFRC). 2. Fireplace surrounds. 3. All decorative applications as countertops. | ||

| Feature | 1. Strengthen the concrete and helps prevent cracking from shrinkage. 2. Replace steel reinforcement in countertops. 3. Suitable for use with any concrete countertop project. | ||

PERFORMANCE ATTRIBUTES

MAKES HIGHLY DURABLE GRC ELEMENTS

REMAINS INTEGRAL DURING MIXING

SUITABLE FOR BOTH PREMIX AND SPRAY

REINFORCED CONCRETE AS A STRUCTURAL MATERIAL

Technical Index

| Yarn Density per Strand(tex) | Content of Fuel(%) | Moisture Content(%) | Length(mm) |

| 98±10 | 1.6±0.2 | ≤0.2 | 6、12、18、24 |

| 58±10 | 1.6±0.2 | ≤0.2 | 6、12、18、24 |

Specification

| Product Code | Unit | ARGCTM12 | ARGCTM18 | ARGCTM24 |

| Fiber Diameter | Microns | 13±2 | 13±2 | 13±2 |

| Chop Length) | mm | 12 | 18 | 24 |

| Linear Density | tex | 76±7 | 76±7 | 76±7 |

| ZrO2 Content | % | ≥16 | ≥16 | ≥16 |

| Moisture Content | % | ≤0.2 | ≤0.2 | ≤0.2 |

| Breaking Strength | N/tex | ≥0.25 | ≥0.25 | ≥0.25 |

APPLICATION

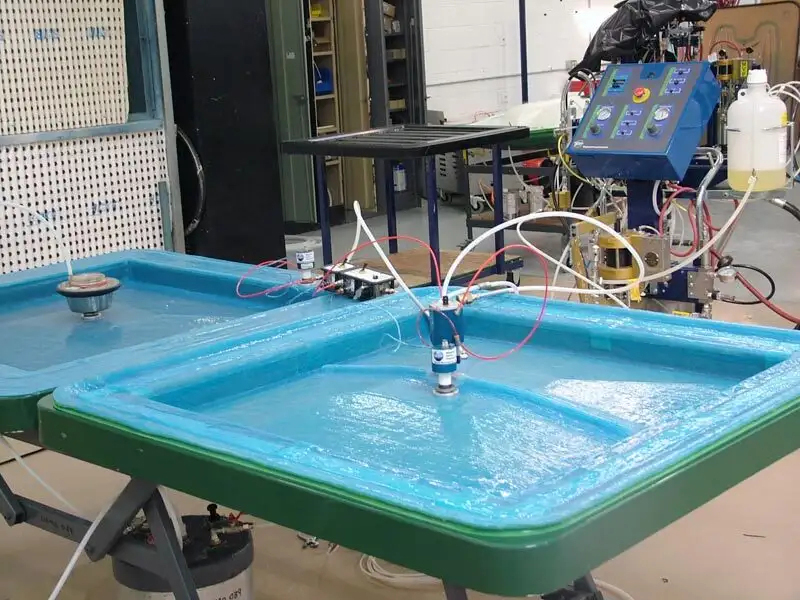

It used in the manufacture of glass fiber reinforced concrete (GRC) composites by both premix and simultaneous spray methods; fireplace surrounds; all decorative applications as countertops.

Molding Technology

Extrusion Molding

Plastic extrusion molding is a method of making heated or unheated pellets pass through a forming hole (die) into a continuous molding product. Due to its wide application, continuous production and high production efficiency, extrusion molding occupies a very important position in the plastic processing industry. At present, extrusion molding products account for more than 1/3 of the total plastic products in my country. Related Products: Thermoplastic Chopped Yarn, Thermoplastic Direct Yarn

Plastic extrusion molding is a method of making heated or unheated pellets pass through a forming hole (die) into a continuous molding product. Due to its wide application, continuous production and high production efficiency, extrusion molding occupies a very important position in the plastic processing industry. At present, extrusion molding products account for more than 1/3 of the total plastic products in my country. Related Products: Thermoplastic Chopped Yarn, Thermoplastic Direct YarnInjection Molding

Injection molding also known as injection molding, is to feed pellets or powdered plastics from the hopper of the injection molding machine into the heated barrel, heat and plasticize into a molten state, and press the screw to pass through the nozzle at the end of the barrel. It is injected into the low-temperature, closed mold cavity, cooled and hardened to maintain the shape given by the mold cavity, and a working cycle is completed after the mold is opened and the colloid is taken out.Advantages: short molding cycle, low energy consumption, high product precision, and complex parts can be formed at one time. Disadvantages: High mold cost, not suitable for small batch products. Related products: Chopped yarn, thermoplastic direct yarn.

Injection molding also known as injection molding, is to feed pellets or powdered plastics from the hopper of the injection molding machine into the heated barrel, heat and plasticize into a molten state, and press the screw to pass through the nozzle at the end of the barrel. It is injected into the low-temperature, closed mold cavity, cooled and hardened to maintain the shape given by the mold cavity, and a working cycle is completed after the mold is opened and the colloid is taken out.Advantages: short molding cycle, low energy consumption, high product precision, and complex parts can be formed at one time. Disadvantages: High mold cost, not suitable for small batch products. Related products: Chopped yarn, thermoplastic direct yarn.