Product Details

| Product name | Fiberglass powder chopped strand mat | ||

| MOQ | ≥1000KG | ||

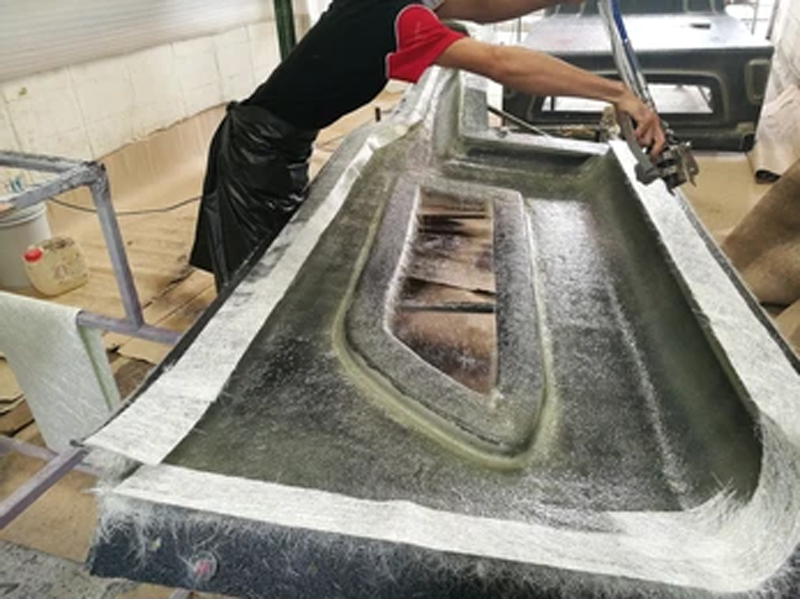

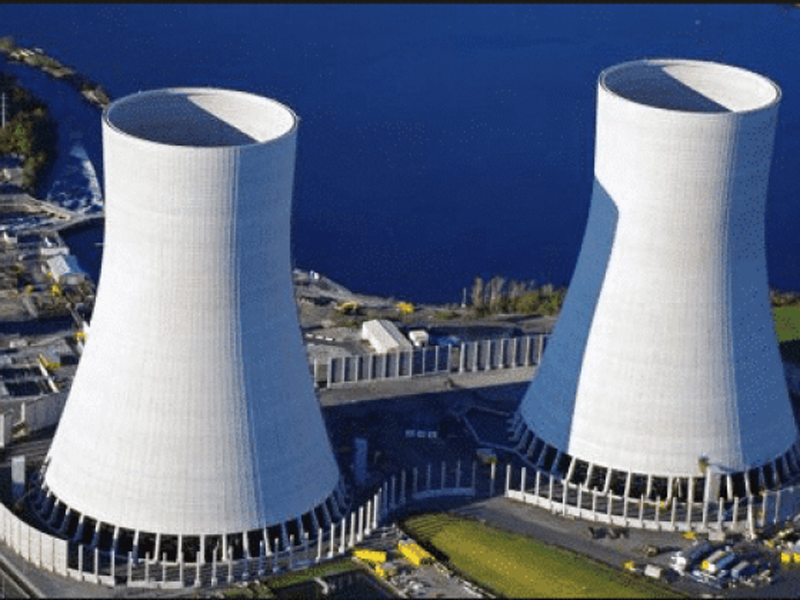

| Application | Suitable for hand lay-up Various FRP products such as plates, lighting panels, hulls, bathtubs, cooling towers, anti-corrosion materials, vehicles, etc. are also suitable for continuous FRP tile units. | ||

| Feature | • The surface of the laminate is smooth and has good light transmission • Fast soaking speed and good mold coverage • Easy to eliminate air bubbles • Good dispersion and uniformity • High wet strength retention • Good mechanical properties | ||

PERFORMANCE ATTRIBUTES

GOOD DISPERSION AND UNIFORMITY

GOOD MECHANICAL PROPERTIES

FAST SOAKING SPEED AND GOOD MOLD COVERAGE

HIGH WET STRENGTH RETENTION

| Product code | Glass type | Unite weight (g/m2) | Width(mm) | Roll weight (kg) | Moisture (%) | Binder content (%) | Binder Type. |

| EMC100 | E/C Glass. | 100+/-20 | 1040-1270 | 30- 50. | <0.2-0.3. | 2-6. | PowderEmulsion |

| EMC150 | E/C Glass. | 150+/-20 | 1040-1270 | 30-50. | <0.2-0.3. | 2-6. | PowderEmulsion |

| EMC200 | E/C Glass. | 200+/-20. | 1040-1270 | 30-50. | <0.2-0.3. | 2-6. | PowderEmulsion |

| EMC300 | E/C Glass. | 300+/-20 | 1040-1270 | 30-50. | <0.2-0.3. | 2-6. | Powder/Emulsion |

| EMC450 | E/C Glass. | 450+/-20. | 1040-1270 | 30-50. | <0.2-0.3. | 2-6. | Powder/Emulsion |

| EMC600 | E/C Glass. | 600+/-20. | 1040-1270 | 30-50. | <0.2-0.3. | 2-6. | Powder Emulsion |

| EMC 900. | E/C Glass. | 900+/-20 | 1040- 1270 | 30-50. | <0.2-0.3. | 2-6. | Powder/Emulsionl |