Products Details

Product Details

| Product name | E-Glass Assembled Roving For Centrifugal Casting |

| MOQ | ≥1000KG |

| Feature | 1. Good dispersion after chopping 2. Good anti-static property 3. Fast and complete wet-out in resin 4. Good refractive index matching between resin and glass fiber 5. Excellent mechanical properties of composite parts |

Technical Index

| Linear density | Moisture content(%) | Combustible content(%) | Stiffness |

| deviation(%) | (mm) |

| ISO1889 | ISO 3044 | ISO 1887 | ISO 3375 |

| ± 5 | ≤0.15 | 1.00±0.15 | 135±15 |

Specification

| Product code | Fiber diameter [μm] | Linear density TEX | Applicable resin | Product features and uses |

| EW412 | 13 | 2400 | UP, VE | ●Soak fast ●Low static electricity ●Good chopping property ●High product strength ●Mainly used in the production of HOBAS pipes |

| EW413 | 12 | 2400 | UP, VE | ●Soak fast ●Low static electricity ●Good chopping property ●High product strength ●Mainly used in the production of continuous winding pipes |

Application

Mainly used to manufacture Centrifugal Casting pipes of various specifications and some special spay-up processes, and used in high-pressure epoxy pipelines, pressure vessels, gas cylinders, medium and low-pressure water pipelines, etc. Contact us, we will send you product information quotations and lightweight solutions!

Advantage

ZBREHON E-Glass Assembled Roving For Centrifugal Casting is formulated with silane-enhanced sizing, which has excellent chopping smoothness, good antistatic and dispersibility, and high product strength. It also has superior mechanical properties, good production process, low hairiness, excellent corrosion resistance; Winding duct yarn for epoxy systems, best suited for epoxy anhydride curing agents and amine curing agents. ZBREHON is mainly engaged in the production of high-performance glass fiber and its products. It has more than 30 categories and more than 230 varieties. It is one of the enterprises with complete varieties of glass fiber industry in China. Now it has mastered the international advanced independent core technology of glass fiber manufacturing, the world's most advanced tank kiln drawing technology has been put into use, and has more than 70 invention patents and practical patents.

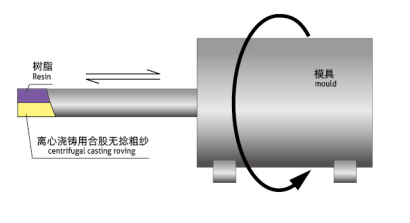

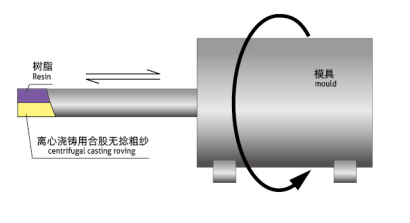

Centrifugal Casting Process

The raw materials, including resin, chopped reinforcement (fiberglass), andfiller, are fed into the interior of a rotating mould according to a specific, proportion. Due to centrifugal force the materials are pressed against the wallof the mould under pressure, and the compound materials are compacted anddeaired. After curing the composite part is removed from the mould.

Alkali-resistant fiberglass roving,

China Pan Fiber and Pan Fiber Filament price,

fiberglass roving price,

factory wholesale fiberglass,

Building materials,

glassfiber roving,

composite glass fiber,

Reinforcement fiberglass for concrete,

AR Fiberglass Roving,

woven roving fiberglass,