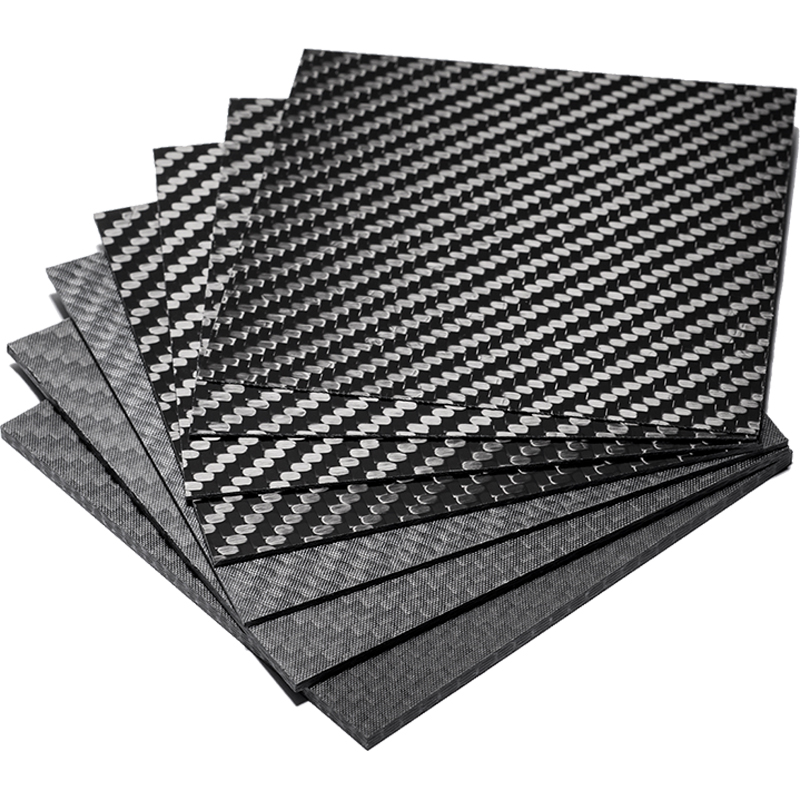

Fiberglass is a reinforced plastic material that is composed of glass fibers embedded in a resin matrix. It is known for its strength, durability, and lightweight properties, making it a popular choice for a wide range of applications. When used in injection molding, fiberglass can be shaped into complex and intricate designs, making it an ideal material for producing a variety of products.

The use of fiberglass for injection molding has become increasingly popular in industries such as automotive manufacturing, where the material is used to produce lightweight and durable parts for vehicles. With the automotive industry's growing emphasis on fuel efficiency and environmental sustainability, fiberglass has emerged as a preferred material for creating components that contribute to lighter and more fuel-efficient vehicles.

In addition to automotive applications, fiberglass for injection molding has also found its way into the aerospace industry, where it is being used to manufacture aircraft components. The material's high strength-to-weight ratio and resistance to corrosion make it an ideal choice for producing parts that must withstand the rigors of flight.

Moreover, fiberglass injection molding has also made inroads into the medical industry, where it is used to create various medical devices and equipment. The material's biocompatibility and resistance to chemicals make it suitable for applications in healthcare, including the production of surgical instruments, medical imaging devices, and implants.

The versatility of fiberglass for injection molding is further demonstrated in its use in the shipbuilding industry, where it is utilized in the construction of marine components and structures. With its ability to withstand the harsh marine environment and resist corrosion, fiberglass has become a preferred material for producing marine equipment, boat hulls, and offshore structures.

Beyond these industries, fiberglass injection molding has applications in architecture and industrial manufacturing, where it is used to create a wide range of products, including building components, consumer goods, and industrial machinery parts.

Zhongbao Ruiheng Technology Co., Ltd. is at the forefront of developing and manufacturing fiberglass for injection molding, offering a comprehensive range of products tailored to meet the specific needs of different industries. The company's Fiberglass Chopped Strands, Fiberglass Roving & Yarn, Chopped Strand Mat, and Glassfiber Cloth are just a few examples of their high-quality fiberglass materials that are widely used in injection molding processes.

As a global leader in the composite materials industry, Zhongbao Ruiheng Technology Co., Ltd. is committed to delivering innovative solutions that meet the demands of modern manufacturing. With a focus on research and development, the company continues to advance its fiberglass technology, ensuring that it remains at the cutting edge of the industry.

The use of fiberglass for injection molding is expected to continue to grow as industries seek lightweight, durable, and cost-effective materials for their manufacturing processes. With its wide-ranging applications and proven performance, fiberglass injection molding is poised to play an increasingly vital role in shaping the products of the future.

In conclusion, Zhongbao Ruiheng Technology Co., Ltd. has established itself as a leading provider of fiberglass for injection molding, offering a range of high-quality materials that are driving innovation across multiple industries. With its commitment to quality, performance, and technological advancement, the company is well-positioned to meet the evolving needs of the global manufacturing sector and continue to emerge as a key player in the composite materials industry.